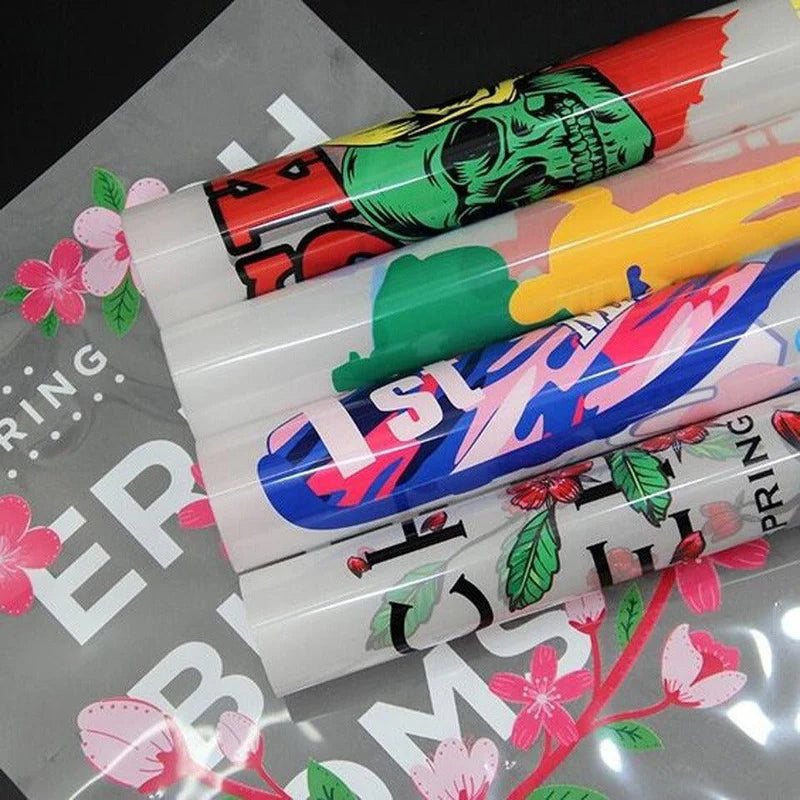

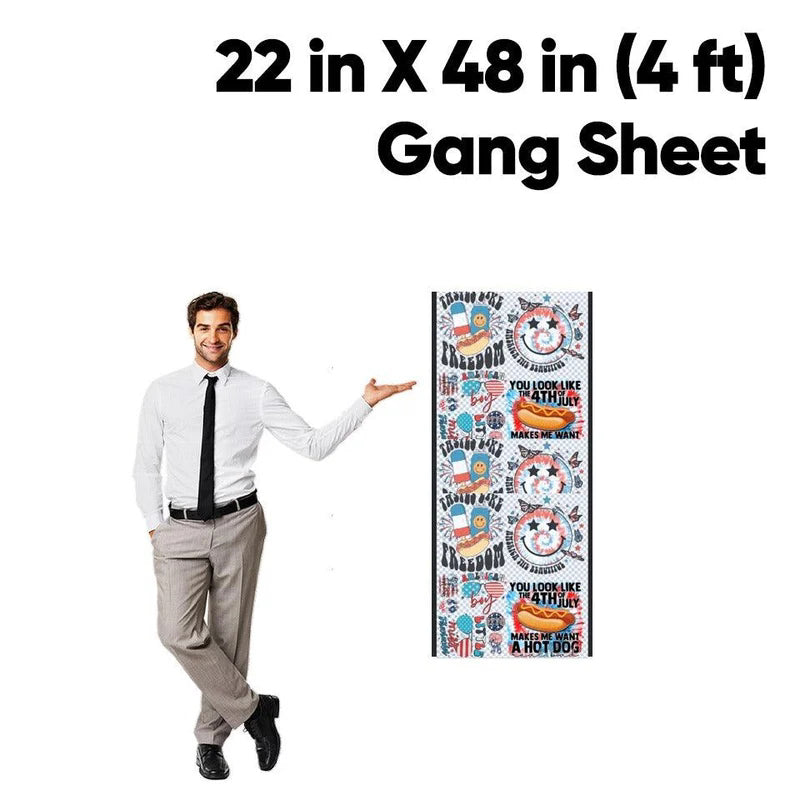

Super quick delivery, extremely easy to use! It was my first time applying transfers and it turned out great for even a newbie like me! I will be ordering all my decals from here from now on!

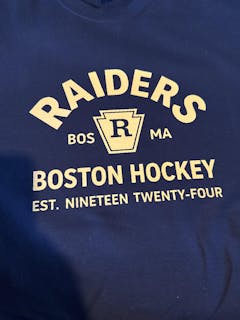

I love the quality of all of their shirts & hoodies. They also offer great DTF prints and the they are VERY timely!! I would HIGHLY RECOMMEND this vendor for personal or business use!!!

Received the order fast and good customer service!

Happy to serve you always , Thank you!

I've used several companies and the print colors were way off. The only problem I found with your transfers is the white is slightly translucent. I have used other companies that the white is much more opaque.

Thanks for the feedback!

We really appreciate you giving us a shot and we're glad the color accuracy stood out compared to others you've tried.

You're right about the white—our standard transfers use a single white underbase which can show slight translucency on darker fabrics. For customers who need maximum opacity, we recommend:

Applying on lighter colored garments for best results

Double-pressing for a more solid finish

Or reaching out to us at info@Ezdtfmaker.com for custom opacity adjustments on future orders

We're always working to dial in quality, so your input helps. Thanks for choosing us, and we'd love to earn your next order! 💪

— The EZDTFMaker Team