DTF printing (Direct-to-Film) is a game-changing method for creating vibrant, durable designs on fabrics and other materials. This innovative printing technique is perfect for small business owners, custom apparel creators, and print shop operators who want professional results without the high setup costs of traditional methods.

Unlike screen printing or vinyl cutting, DTF printing lets you transfer detailed, full-color designs directly onto almost any material using special films and powders. The process works on cotton, polyester, blends, leather, and even some hard surfaces.

In this guide, we'll break down how DTF printing technology actually works and what makes it different from other printing methods. You'll learn about the essential equipment and materials you need to get started, plus we'll walk you through the complete step-by-step process from design to finished product. We'll also cover the key advantages that make DTF printing stand out and explore the most popular applications across different industries.

Understanding DTF Printing Technology

Direct-to-Film Printing Process Explained

Direct-to-Film (DTF) printing works by printing designs onto a special PET film using water-based inks, then applying hot-melt adhesive powder to create transfers that can bond to various fabrics. The process starts with creating your design digitally, then printing it in reverse onto the clear film using specialized DTF inks. These inks contain white ink as a base layer, which makes colors pop on dark fabrics.

The magic happens when hot-melt powder gets sprinkled over the wet ink. This powder melts and cures when heated, forming a flexible adhesive layer that bonds the design to fabric when heat pressed. The result is a durable, vibrant print that feels soft and stretches with the material.

How DTF Differs from Traditional Printing Methods

DTF stands apart from screen printing, vinyl cutting, and direct-to-garment (DTG) printing in several key ways. Screen printing requires separate screens for each color and works best for large quantities, while DTF handles full-color designs in single pieces just as easily as bulk orders.

| Method | Setup Time | Color Limitations | Fabric Types | Minimum Orders |

|---|---|---|---|---|

| DTF | Minimal | Unlimited | All types | Single piece |

| Screen Printing | High | Limited by screens | Cotton preferred | 50+ pieces |

| DTG | Moderate | Unlimited | Cotton/cotton blends | Single piece |

| Vinyl | Low | Limited by material colors | Most fabrics | Single piece |

Unlike DTG printing, which prints directly onto garments and works best on light-colored cotton, DTF creates transfers that work on any fabric color and blend. You can print on polyester, cotton, blends, leather, and even hard surfaces.

Key Components Required for DTF Printing

A complete DTF setup needs several essential components working together. The DTF printer serves as the foundation - typically a modified inkjet printer equipped with DTF inks including cyan, magenta, yellow, black, and white. The white ink acts as the base layer and requires constant circulation to prevent settling.

DTF films are specially coated PET films designed to accept the inks properly and release cleanly during transfer. These films come in different thicknesses and release properties depending on your application needs.

The powder shaker applies hot-melt adhesive powder evenly across the printed design while the ink is still wet. This powder comes in different mesh sizes and melting points to match various fabric types and desired hand-feel.

A curing oven or conveyor dryer melts and sets the adhesive powder, typically at temperatures around 160-170°C for 2-3 minutes. Finally, a heat press applies the cured transfer to the garment using controlled temperature, pressure, and time.

Advanced Adhesive Powder Application System

The adhesive powder application represents the most critical step in DTF printing quality. Modern powder shakers use vibrating mesh systems that distribute powder particles uniformly across the printed area. The powder must contact the wet ink within 30-60 seconds of printing to achieve proper adhesion.

Professional systems include powder recovery mechanisms that collect excess powder for reuse, reducing waste and operational costs. Some advanced units feature adjustable vibration speeds and powder flow controls to optimize coverage for different design types and ink coverage levels.

The curing process activates the adhesive properties through controlled heat application. Proper curing creates cross-links in the adhesive that provide wash durability while maintaining flexibility. Under-cured powder results in poor adhesion, while over-curing can make transfers brittle and prone to cracking.

Quality powder systems maintain consistent particle size distribution and melting characteristics. Premium powders include additives that improve wash resistance, reduce hand-feel, and enhance color vibrancy of the final transfer.

Explore More with EZT Mart & EZDTF Maker

At EZDTF Maker, we provide everything you need to bring your designs to life — from blank apparel to premium DTF and UV DTF printing supplies. Start with our apparel mart, then explore our full range of transfers, bundles, and materials.

🛍 Shop Apparel & Blanks

Begin your printing journey with high-quality apparel from our dedicated store:

👉 EZT Mart – Your destination for blank apparel, fashion basics, and accessories ready for customization.

Custom Transfers & Builders

Custom DTF Transfers by Size – Perfectly sized transfers for any project.

DTF Gang Sheet Builder – Combine multiple designs into one efficient sheet.

Upload Your Gang Sheets – Quick uploads for fast turnaround.

Holiday & Seasonal Transfers – Ready-to-press designs for special occasions.

UV DTF Gang Sheet Builder – Create vibrant and durable UV DTF stickers.

Bundles & Supplies

DTF Supplies Bundle | UV DTF Supplies Bundle – All-in-one solutions for your printing setup.

Premium DTF Ink | DTF TPU Powder | DTF Film Rolls – Reliable supplies for flawless results.

UV DTF Ink | Premium UV DTF Film – High-quality UV materials for lasting designs.

Essential Equipment and Materials for DTF Success

Professional DTF printers and specifications

DTF printing demands specialized printers designed to handle the unique requirements of direct-to-film technology. Modified inkjet printers, typically based on Epson EcoTank or similar models, serve as the foundation for most DTF setups. These printers require specific modifications including specialized print heads capable of handling DTF inks and maintaining consistent flow rates.

Key specifications to look for include print resolution of at least 1440 dpi for sharp detail reproduction, multiple ink channels supporting CMYK plus white ink systems, and robust construction capable of continuous operation. Print width options range from desktop A4 models to wide-format 24-inch systems, with larger formats enabling higher production volumes and cost efficiency for commercial operations.

Temperature control becomes critical, as DTF inks perform optimally within specific temperature ranges. Many professional DTF printers include heated platens or environmental controls to maintain consistent ink viscosity and flow characteristics.

High-quality DTF films and their properties

DTF films serve as the transfer medium, making their quality absolutely essential for successful prints. Premium films feature specialized coatings that accept DTF inks while maintaining dimensional stability during the printing and curing process.

The film thickness typically ranges from 0.75 to 1.0 mil, balancing flexibility with durability. Quality films exhibit excellent ink adhesion properties, preventing ink bleeding or smudging during printing. Transparency levels vary, with most films offering slight translucency that allows for registration and quality control during printing.

Storage requirements include maintaining films in controlled temperature and humidity environments, as excessive moisture can compromise adhesion properties. Roll widths should match printer capabilities, with common sizes including 13", 17", and 24" widths.

Specialized inks for vibrant color reproduction

DTF inks represent a specialized formulation designed specifically for direct-to-film applications. These water-based inks contain unique additives that promote adhesion to both the transfer film and the final substrate after heat application.

White ink plays a particularly crucial role in DTF printing, serving as both a base layer for vibrant colors on dark substrates and as a final layer to enhance opacity. White ink requires frequent agitation during printing to prevent settling and maintain consistent coverage.

Color inks must demonstrate excellent wash fastness, maintaining vibrancy through repeated laundering cycles. UV resistance prevents fading from sun exposure, while the ink formulation must remain flexible after curing to prevent cracking on fabric substrates.

Storage considerations include temperature control and regular agitation systems for white inks. Shelf life typically ranges from 12-24 months when stored properly, with opened bottles requiring use within shorter timeframes to maintain optimal performance.

Heat press requirements for perfect transfers

Heat press specifications directly impact transfer quality and durability. Commercial-grade heat presses with even temperature distribution across the entire platen surface prevent hot spots that can cause uneven adhesion or film burning.

Temperature accuracy within ±5°F becomes essential, as DTF transfers require precise temperature control typically ranging from 300-320°F. Pressure settings must be adjustable and consistent, with most DTF applications requiring moderate to firm pressure for proper adhesion without damaging delicate films.

Platen size should accommodate your typical job sizes, with larger platens enabling greater production efficiency. Pneumatic or hydraulic systems provide more consistent pressure than manual lever systems, particularly important for commercial operations requiring repeatable results across multiple transfers.

Timer functions with both audible and visual alerts prevent over-pressing, while Teflon sheets or parchment paper protect both the heat press and the transfer during application.

Step-by-Step DTF Printing Process

Design Preparation and File Optimization

Your design file makes or breaks the entire DTF printing process. Start with high-resolution artwork - aim for 300 DPI minimum to avoid pixelated results. Vector graphics work best, but high-quality raster images can deliver excellent results too.

Color management plays a crucial role in achieving vibrant prints. Convert your design to CMYK color mode and adjust for the specific DTF film you're using. Many DTF printers work best with designs that have rich, saturated colors since the white ink layer underneath enhances the final appearance.

Size your artwork according to the final application, adding a small bleed area around the edges. This prevents white margins and ensures complete coverage. Save your file in formats like PDF, AI, or high-resolution PNG to maintain quality throughout the printing process.

Consider the fabric color when preparing your design. Dark garments require a solid white ink base layer, while light-colored fabrics might need minimal or no white ink backing. Design software like RIP programs can help optimize ink usage and layer separation automatically.

Printing Technique for Optimal Results

DTF printing requires a specific sequence to achieve professional results. Begin by loading your DTF film with the coated side facing up in your printer. The coating helps the inks adhere properly and prevents bleeding.

Print your design in reverse (mirrored) since you'll be transferring it onto fabric. Most DTF printers use a four-color CMYK setup plus white ink. The white ink acts as a base layer that makes colors pop and provides opacity for dark fabrics.

Maintain consistent room temperature and humidity levels during printing. High humidity can cause ink bleeding, while low humidity might lead to poor adhesion. The ideal range sits between 45-55% relative humidity.

Print speed affects quality significantly. Slower printing speeds typically produce better color saturation and detail reproduction. Start with manufacturer recommendations and adjust based on your specific results. Multiple passes at lower speeds often outperform single high-speed passes.

Powder Application and Curing Methods

Hot melt adhesive powder application requires precision and timing. Apply the powder immediately after printing while the inks remain wet - this usually means within 30-60 seconds of printing completion.

Shake the powder evenly across the entire printed surface using a fine mesh shaker or powder application machine. The powder particles will stick only to the wet ink areas, creating the adhesive layer needed for transfer.

Remove excess powder by gently tapping or shaking the film. You can reuse this excess powder, making the process cost-effective. Some operators use a soft brush to ensure even powder distribution and remove any clumps.

Curing transforms the powder into a solid adhesive layer. Use a heat press or conveyor dryer set to 160-170°C for 2-3 minutes. The powder should melt completely and create a smooth, even surface. Proper curing creates a flexible bond that won't crack during application.

Allow the DTF transfer to cool completely before peeling the carrier film. This cooling period helps the adhesive set properly and ensures clean separation from the backing material.

Advantages of DTF Printing Over Other Methods

Superior durability and wash resistance

DTF prints create an incredibly strong bond with fabric that outperforms many traditional printing methods. The adhesive powder used in the DTF process forms a flexible yet durable layer that moves with the fabric rather than cracking or peeling. This flexibility means your designs stay vibrant and intact through countless wash cycles.

Unlike vinyl transfers that can lift at the edges or screen prints that fade over time, DTF transfers maintain their integrity even after 50+ washes. The prints resist cracking, fading, and peeling because the ink penetrates through the adhesive layer and bonds directly with the fabric fibers. This creates a print that feels soft to the touch while maintaining excellent durability.

Cost-effectiveness for small and large runs

DTF printing shines in both low-volume and high-volume production scenarios. For small orders, you don't need to create screens or plates like traditional screen printing, eliminating setup costs and minimum order requirements. You can literally print one shirt as cost-effectively as you can print ten.

For larger runs, DTF maintains its efficiency because the process doesn't require lengthy setup times or color separations. The digital nature means you can switch between designs instantly without cleaning screens or changing inks. This flexibility translates to significant cost savings, especially when dealing with multiple design variations or color combinations.

| Print Method | Setup Cost | Per Unit Cost (Small) | Per Unit Cost (Large) |

|---|---|---|---|

| DTF | Low | $2-4 | $0.50-1.50 |

| Screen Print | High | $8-12 | $0.30-0.80 |

| Vinyl | Medium | $3-6 | $1.50-3.00 |

Versatility across multiple fabric types

DTF technology works exceptionally well on cotton, polyester, blends, canvas, denim, and even challenging materials like nylon and leather. This versatility eliminates the need for different printing methods based on fabric type, streamlining your production process.

The adhesive powder formulation bonds effectively with both natural and synthetic fibers, creating consistent results across material types. You can print the same design on a cotton t-shirt and a polyester athletic jersey using identical settings and materials. This consistency reduces inventory complexity and simplifies your workflow.

DTF also handles fabric colors beautifully. The white ink base layer ensures vibrant colors pop on both light and dark fabrics without requiring separate processes or additional steps.

Simplified workflow and faster production times

DTF printing streamlines the entire production process from design to finished product. The workflow involves printing, applying powder, curing, and pressing – that's it. No weeding, no masking, no multiple color alignments.

The digital nature means design changes happen instantly in software rather than requiring physical modifications. You can print multiple designs simultaneously on the same sheet, maximizing material usage and reducing production time. A single operator can manage the entire process, from printing transfers to applying them to garments.

Production speed increases dramatically because you can batch print transfers ahead of time and store them for later use. This separation of printing and application means you can optimize each step independently, leading to faster turnaround times and better resource utilization.

Common Applications and Industries Using DTF

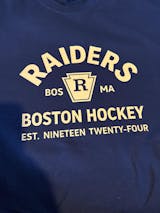

Custom apparel and fashion businesses

DTF printing has revolutionized how custom apparel businesses operate, offering unmatched versatility and quality that traditional methods simply can't match. Small startups can now compete with larger manufacturers by producing professional-grade custom shirts, hoodies, and accessories without massive upfront investments in screen printing setups or embroidery equipment.

Fashion entrepreneurs love DTF because it handles complex designs with multiple colors effortlessly. Whether creating vibrant graphic tees, detailed artwork on premium garments, or personalized merchandise for online stores, DTF delivers consistent results that customers rave about. The technology works beautifully on cotton, polyester, blends, and even tricky fabrics like denim or canvas.

Print-on-demand businesses particularly benefit from DTF's flexibility. Orders can be fulfilled individually without minimum quantities, making it perfect for testing new designs or serving niche markets. The durability of DTF prints means fewer customer complaints about cracking or fading, building stronger brand reputation and repeat business.

Sports teams and promotional merchandise

Sports organizations at every level have embraced DTF printing for uniforms, fan gear, and promotional items. High school teams can now afford custom jerseys with detailed logos and player names without breaking their budgets. The prints withstand intense washing cycles and maintain vibrant colors through countless games and practices.

Corporate promotional merchandise has found a perfect partner in DTF technology. Companies can create memorable branded items like branded apparel, bags, and accessories that actually get used rather than tossed aside. The professional finish and durability make recipients more likely to wear or display these items, extending brand visibility.

Event merchandise represents another growing application. Concerts, festivals, and conferences use DTF to create limited-edition items that become coveted keepsakes. Quick turnaround times allow organizers to capitalize on last-minute design changes or popular trends.

Home decor and textile manufacturing

DTF printing has expanded beyond clothing into home decor applications, transforming how manufacturers approach textile customization. Custom pillows, curtains, wall hangings, and upholstery now feature intricate designs that were previously impossible or cost-prohibitive to produce.

Interior designers appreciate DTF's ability to create matching textile sets with consistent color reproduction across different fabric types. Hotels and restaurants use the technology for branded linens, custom table runners, and decorative elements that reinforce their unique aesthetic while maintaining commercial durability standards.

The craft and DIY market has exploded with DTF applications. Small manufacturers produce transfer sheets for hobbyists who want professional results at home. This democratization of high-quality printing has spawned countless small businesses and creative ventures, from personalized baby blankets to custom pet accessories.

DTF printing has transformed how we approach custom apparel and textile decoration, offering a versatile solution that works across different fabric types without the limitations of traditional methods. From understanding the core technology to mastering the equipment setup, film preparation, and heat press application, this printing method delivers professional results with vibrant colors and excellent durability. The ability to print on cotton, polyester, blends, and even challenging materials like leather makes DTF a game-changer for businesses looking to expand their product offerings.

The competitive advantages are clear – no pretreatment requirements, white ink capabilities, and cost-effective production for both small runs and bulk orders. Whether you're running a small custom apparel business, managing promotional product campaigns, or operating in the sports merchandise industry, DTF printing opens doors to creative possibilities that were once complicated or expensive. Start exploring DTF technology today and discover how this innovative printing method can elevate your business and meet the growing demand for high-quality, customized products.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.